Flutes are the helical grooves that wrap around the sides of the end mill. Each flute has a single tooth with a sharp cutting edge (although there can be more than one) that runs along the edge of the flute.

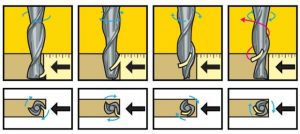

As the tooth cuts into the wood, each flute whisks away a small section or “chip”. The fewer the flutes, the more material that is ejected with each tool rotation. The overall cutting depth should never exceed the length of the flutes on an end mill. If cutting deeper than the length of the flutes, the tops of the flutes will be blocked and chips won’t clear, building up heat and reducing tool life.

Chipload is the thickness of a machined chip as cut by a specific tool type. More flutes create a smoother surface finish, while fewer flutes remove material fastest, but make rougher cuts.

Proper chipload is important because chips dissipate heat. Hot cutters can lead to suboptimal results, including burned wood, a poor edge finish and dull tooling.

If you’re machining a material like HDPE plastic, you want to use an “O” or single flute bit to clear the chips away as quickly as possible or heat will build up melting the plastic, which will “reweld” to the tool.

To summarize:

More flutes create a smoother surface finish

Fewer flutes are best at chip clearing, keep heat from building up

Two or four flute cutters are the most common.

The direction, size, speed and amount of chips being ejected can also damage the surface of the work piece. We can control how the tooling effects the material through our end mill type selection (upcut, downcut or compression) and speed at which we cut.